HOMER Pro 3.16

![]()

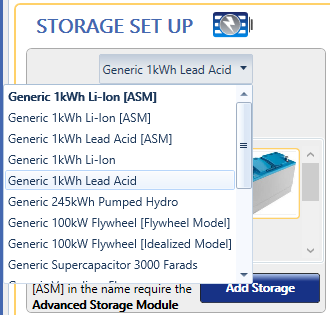

The Storage page allows you to choose a storage component from the library, look at the technical details, and specify storage costs. You can define new storage models in the Storage Library or select from existing options.

There are several types of storage components:

•Idealized Battery: The idealized battery model allows users to size energy and power independently.

•Kinetic Battery: The Kinetic Battery model is a two-tank system, that separates available energy for electricity generation from bound energy that cannot be used.

•Modified Kinetic Battery: The Modified Kinetic Battery Model accounts for rate dependent losses, temperature dependence on capacity, and temperature effects on calendar life.

•Supercapacitor: The Supercapacitor is based on the Idealized Storage Model, which replicates a simple storage model with a flat discharge curve because the supply voltage stays mostly constant during the discharge cycle.

•Flywheel: A flywheel provides operating reserve on the AC bus, helping to absorb sudden increases or make up for sudden decreases in renewable power output.

•Pumped Hydro: A Pumped Hydro System builds potential energy by storing water in a reservoir at a certain height when there is excess energy, and converts the potential energy to electricity by releasing the potential energy to turn the turbine generator when there is a demand.

Select a Storage Component from the drop-down menu on the left side of the Storage Set Up page. Click the Add Storage button to add the selected storage to your model. If the component you want is not listed, click the Complete Catalog button to see all the options in the your library, including the built-in items included with HOMER (in regular font) and those you created or imported into your personal library (in bold font).

Important: Components with [ASM] after the name require the Advanced Storage Module. See Adding Modules for more information on purchasing modules.

The Storage page appears. You can navigate between the Storage Set Up page and one or more Storage pages using the tabs at the top of the page or by clicking the appropriate icon in the Schematic on the left side of the page.

![]()

HOMER can only simulate one storage component at a time with one exception. HOMER can include one flywheel storage component in addition to any one other type of storage component. You can add more than one storage component to the model, but each one must include a zero in the Search Space. HOMER simulates each of the storage types, one component at a time.

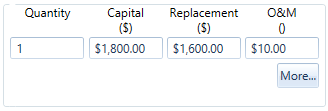

Costs

The cost table includes the initial capital cost and replacement cost per storage item, as well as annual operation and maintenance (O&M) costs per storage. When specifying the capital and replacement costs, be sure to account for all costs associated with the storage, including installation and power electronics.

Note: The Capital cost is the initial purchase price. The Replacement cost is the cost of replacing the storage at the end of its lifetime. The O&M cost is the annual cost of operating and maintaining the storage.

Note: Below each numerical input is a sensitivity button ( ) that allows you to do a sensitivity analysis on that variable. For more information, see Why Would I Do a Sensitivity Analysis?

) that allows you to do a sensitivity analysis on that variable. For more information, see Why Would I Do a Sensitivity Analysis?

Cost Curve

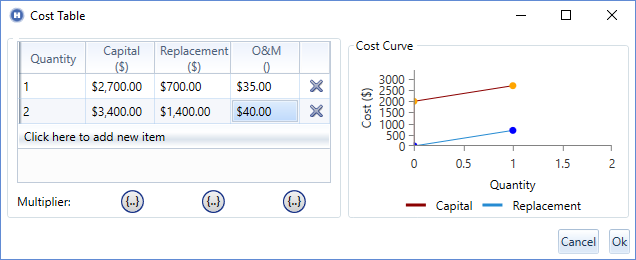

In the cost table, enter the cost curve in as much detail as you want. This example uses batteries, although the storage component can be a variety of energy storage technologies.

If each battery costs the same regardless of how many you purchase, you only need to enter data in the basic cost table. Enter a quantity of one, along with the per-component capital, replacement, and operating and maintenance costs. In the example above, each battery costs $1,800 initially, $1,600 to replace, and $10 annually for operating and maintenance. HOMER extrapolates these costs as needed. If you model a system with three batteries, the associated capital, replacement, and O&M costs are three times the values entered in the cost table.

If you want the battery bank's costs to vary with quantity (i.e., the per item cost might be lower for larger quantities), click the More... button and enter multiple rows in the cost table. In the example below, the fixed cost of the battery bank is $2,700 initially plus $35/yr for operating and maintenance. (This could be the cost of a room or a building used to house the batteries.) Each battery then costs $700 plus $5/yr for operating and maintenance.

The capital cost is the initial purchase price, the replacement cost is the cost of replacing the batteries at the end of their lifetime, and the O&M cost is the annual cost of operating and maintaining the battery bank.

Note: HOMER does not assess this $2,000 capital cost for a system that contains zero batteries. It applies only to systems containing battery banks. To add a fixed capital or O&M cost, see Economics.

HOMER uses the number of batteries/strings you entered in the cost table to calculate the corresponding costs, interpolating and extrapolating as necessary.

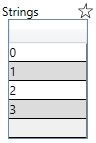

Search Space with Strings

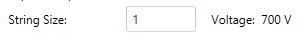

Two or more batteries connected in series form a string. Strings connected in parallel form a storage bank. Idealized, Kinetic, and Modified Kinetic energy storage models include the string size input. If the string size is greater than one, the sizes to consider table shows numbers of strings.

The cost table quantity always refers to the number of batteries, not the number of strings. In results tables and graphs, HOMER always displays the number of batteries, regardless of how you specify the number of batteries in the Seach Space table.

HOMER shows the DC bus voltage in parentheses next to the number of batteries per string. (The bus voltage is the storage's nominal voltage multiplied by the number of storage items per string.) You can use that to decide how many storage items to use per string.

Tip: If you only want to determine the optimal storage capacity, you can set the string size to one and ignore the bus voltage. This approach might be appropriate for a preliminary sizing analysis.

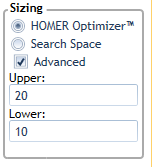

Click the Optimizer option to enable the optimizer. The Advanced option allows you to set a lower bound and an upper bound. With the Optimizer turned on, HOMER automatically finds the best quantity for you.

Tip: If you are considering a small number of batteries (i.e. 0, 1, or 2), enter quantities in the Search Space only, and do not use the optimizer. If you are considering four or more different quantities of batteries, use the optimizer.

See the Optimization page for a more detailed explanation of HOMER's optimizer.

Storage Inputs

Variable |

Description |

String size |

A string is a set of storage items connected in series. The number of storage items per string multiplied by the nominal voltage is the bus voltage. |

Initial State of Charge |

The state of charge of the storage bank at the beginning of the HOMER simulation, in %. |

Minimum State of Charge |

A lower limit on the state of charge of the storage bank, in %. |

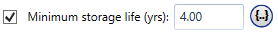

Enforce Minimum Storage Life |

Enable the Minimum Storage Life constraint. |

Minimum Storage Life |

A lower limit on the lifetime of the storage bank. (Systems that do not meet this constraint are discarded as infeasible.) |

Note: To the right of each numerical input is a sensitivity button ( ) that allows you to do a sensitivity analysis on that variable. For more information, see Why Would I Do a Sensitivity Analysis?

) that allows you to do a sensitivity analysis on that variable. For more information, see Why Would I Do a Sensitivity Analysis?

Minimum Storage Life

The minimum storage life is a lower limit on the lifetime of the storage bank. This constraint is not normally necessary, but you can use it if necessary to prevent HOMER from recommending a relatively small storage bank that lasts an unacceptably short time.

For example, HOMER may determine that the optimal system contains a small storage bank that lasts only 1.5 years before needing replacement. If that 1.5-year replacement cycle is unacceptably short, you can implement a minimum 4-year storage lifetime, which causes HOMER to discard that optimal system and choose another, probably with a larger storage bank. It would be a more expensive system (otherwise it would have been optimal without the storage life constraint), but it would conform to the constraint.

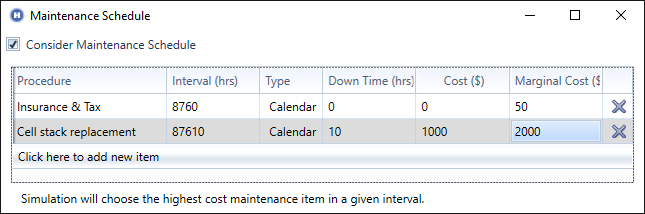

Maintenance Schedule

To enter maintenance events, click the Maintenance Schedule button in the lower-right corner of the Storage Design Inputs page. The Maintenance Schedule window opens. You can specify the maintenance schedule instead of, or in addition to, the O&M cost you specify in the cost table.

The Maintenance Schedule allows you to input costs and/or downtime that occur at regular intervals. Check the Consider Maintenance Schedule box to enable the Maintenance Schedule table, and include maintenance events in the simulation and economics calculations. The example below includes taxes and insurance as a yearly cost (8,760 calendar hours, which is once per year). The cell stack replacement after ten years is also included, with a downtime of ten hours.

Note: An event that occurs every 8,760 Calendar hours (once per year) only occurs 24 times in a 25 year project. The event occurs at the end of every year from the first year to the 24th year, but not at the end of the 25th year.

The cost of each maintenance event is defined in terms of a Cost (fixed cost) and a Marginal Cost. The fixed cost is assessed the same way regardless of the Search Space value being simulated. The Marginal Cost is multiplied by the value in the Search Space and added to the fixed cost to determine the total cost of the maintenance procedure. The Insurance and Tax event costs $50 per unit. So for a quantity or capacity of one for that storage component, the total cost per year for this item is $50. If the Search Space contains a 3, the simulation for a quantity of 3 uses $150 per year for the Insurance and Tax event.

Note: HOMER can only model the downtime for a maintenance event if it occurs in the first year, or if you are running HOMER in Multi-year mode.

The cell stack replacement fixed cost is $1000, which might be the cost for the technician to come to the site and disconnect the battery bank as a whole to prepare it for service. This cost is assessed regardless of the size or quantity of the storage component. The marginal cost for this item is $2000, which might be the cost of the materials, plus the cost of the technician's time to replace the cell stacks in each battery. To continue with the example above, in the simulation with a size or quantity of one, the total cost of cell stack replacement would be $3000 every ten years. For the simulation with the Search Space entry of 3, the cost would be $7000 ($1000 + 3 x $2000).

Note: HOMER does not model the storage charge controller as a separate component. You must include its cost and efficiency in the values you specify for the storage or in other components in the system.

See also