HOMER Pro 3.16

![]()

The Electrolyzer page contains the cost and performance inputs for the Electrolyzer, which generates hydrogen from electricity.

HOMER models the Electrolyzer in a very simple way. The user is able to specify efficiency under the "site-specific" tab in either the box or by using the efficiency table. It assumes a constant efficiency that the user can specify so that a certain amount of electricity will always result in a certain amount of hydrogen. It has a minimum load level, so if the Electrolyzer can only operate down to 75% of its rated capacity for example, you can set the minimum load to 75%.

Normally the Electrolyzer receives only excess electricity (or surplus electricity) or can be supplied by the grid when grid connected, but when hydrogen is needed (to serve the hydrogen load or to fuel a generator required to serve an electric load) the Electrolyzer will demand electricity.

Costs

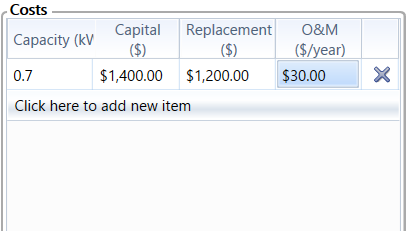

In the electrolyzer Costs table, enter the electrolyzer cost curve; i.e., the way the cost varies with size. Click the "Click to add new item" option to add more rows to the table.

If you have a particular electrolyzer in mind, you can enter its size and cost. In the example above, a 0.7 kW electrolyzer costs $1400 initially, $1200 to replace at the end of its life, and $30/yr for operation and maintenance.

Sizes

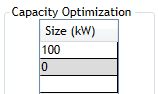

In the Capacity Optimization table, enter the electrolyzer sizes you want HOMER to consider as it searches for the optimal system. Be sure to include a zero size if you want to consider systems without an electrolyzer.

HOMER uses the information you entered in the cost table to calculate the costs of each electrolyzer size, interpolating and extrapolating as necessary. You can see the results in the cost curve graph.

Properties

Variable |

Description |

Lifetime |

The number of years the electrolyzer is expected to last before it requires replacement |

The energy content (based on the higher heating value) of the hydrogen produced divided by the amount of electricity consumed |

|

Minimum Load Ratio |

The minimum power at which the electrolyzer can operate, as a fraction of its rated capacity |

Electrical Bus |

Whether the electrolyzer consumes alternating current (AC) or direct current (DC) power |

Electrolyzer Efficiency

HOMER allows the user to implement an efficiency table to set parameters such as input percentage and efficiency that determine the performance of an electrolyzer. More than one pair of these factors can be considered by clicking "Click here to add new item".

The input percentage represents the electrical energy that is used by the electrolyzer for the electrolysis process. For each given input percentage, the electrolyzer operates at a given efficiency. Efficiency considers the effectiveness of energy conversion as some energy may be lost or dissipated.

For example, an input percentage of 80% and an efficiency of 90% means that out of the total electric energy supplied to the electrolyzer, only 80% is used while the 20% is dissipated. The electrolyzer is 90% successful in converting this energy into hydrogen.

Note: This table uses linear interpolation between rows of the given values.

Note: To the right of each numerical input is a sensitivity button ( ) that allows you to do a sensitivity analysis on that variable. For more information, see Why Would I Do a Sensitivity Analysis?

) that allows you to do a sensitivity analysis on that variable. For more information, see Why Would I Do a Sensitivity Analysis?